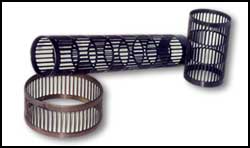

Whether you need long or short runs, we can stamp parts from most materials (steel, galvanized steel, brass, copper and aluminum) including those requiring secondary operations as we have done for the filter, hardware, computer and communications industries.

Design Considerations

Stamping is an economical way to form metal components with a variety of characteristics including strength, durability, and wear resistance. Stamped parts will also have good conductive properties and stability.

A typical metal stamping process is the die-cut which drives a sharpened tool steel punch through the sheet or strip material into a die cavity, where the slug or scrap is ejected. Cutting clearances between the punch and die are closely defined and specified in the die design stage, based on the requirement of the part. The die-cut stamping process produces a very predictable edge condition on the finished part.

Steel grade and blank thickness specifications are two factors that can drive up the cost of metal stamping. Other factors to consider include material properties, steel thickness and flatness of the coil material.